The Greatest Guide To Plant Conveyors And Systems

Table of ContentsThe Best Strategy To Use For Plant Conveyors And SystemsFascination About Plant Conveyors And SystemsPlant Conveyors And Systems for DummiesPlant Conveyors And Systems Fundamentals ExplainedThe Buzz on Plant Conveyors And Systems

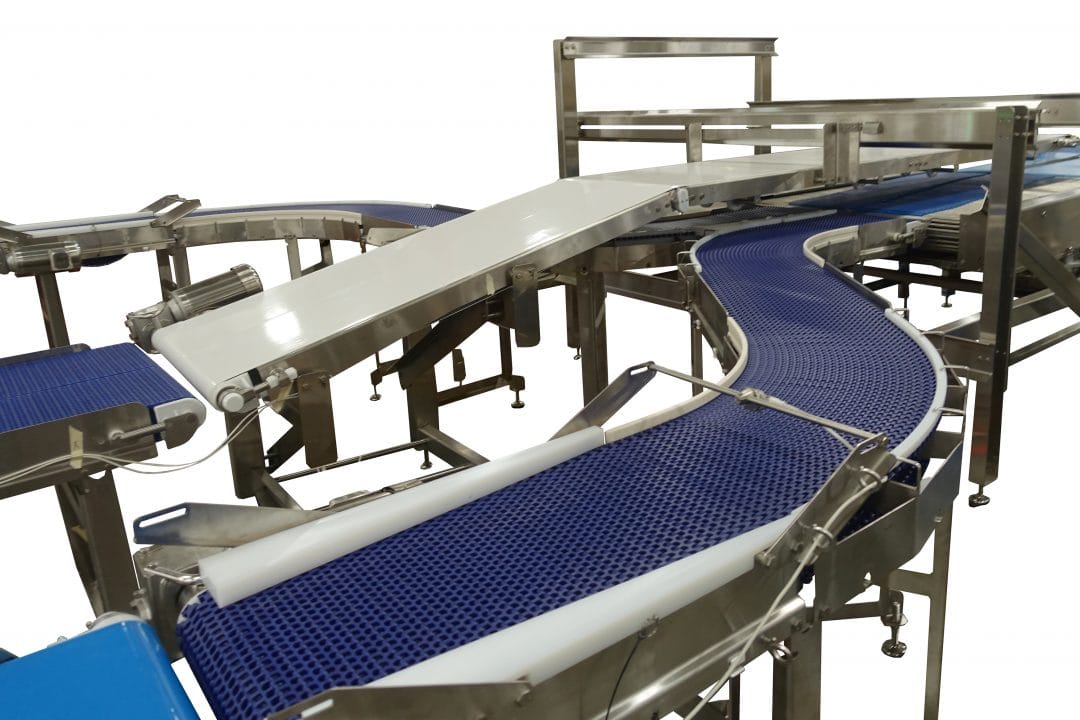

They usually have a system of gears run by an electric motor. Variable speed drives have actually become popular for modern-day sharing because they enable adjustments of product flow. Security: Conveyor systems are controlled by the Occupational Safety And Security and Health And Wellness Management (OSHA) as well as need to fulfill government safety and security demands. All conveyor producers are aware of the laws and also abide by them.Belt Conveyors Belt conveyors are the most typical and most basic form of conveyor and can have variable speeds. They have a moving belt that rests on a steel framework that sustains the belt and the products being relocated. Ones that have a supporting frame below are referred to as sliding style.

Gravity Roller Conveyors Gravity roller conveyors have a collection of just as spaced rollers connected to a side structure. The placement of the rollers gives a surface to place products for activity. If a gravity roller conveyor is slanted or installed on an angle, products move by gravity. Items of varying sizes can be filled on a gravity roller conveyor, employees need to be mindful of bigger materials running right into smaller ones.

Chain Conveyors Chain conveyors can have 2 or a number of sets of chains that reach the base of things to be moved - Plant Conveyors and Systems. The products hinge on the chains as they are relocated. Chain driven conveyors are ideal for things with uneven lower surface areas or ones that are really heavy.

Fascination About Plant Conveyors And Systems

Because of the kinds of products chain conveyors move, they operate very slowly. Motorized Roller Conveyors Motorized roller conveyors make use of electric motors, put along the conveyor structure, to power evenly spaced rollers. The layout resembles a gravity conveyor with the enhancement of motors. The variety of motors depends on the load to be relocated and also the total style of the system.

In some systems, there is a sensing unit that begins and quits the motor to avoid pieces getting compacted. Slat Conveyors Slat conveyors have the very same layout as chain conveyors with level slats linked to the chain. Somehow, they resemble belt conveyors with slats changing the belt.

Open Up Track Conveyors - Open track conveyors do not cover the track and usage I beams as the track. Chain Expenses Conveyors - Chain overhead conveyors make use of a continuous powered chain that runs along a track.

In other styles where necklaces are not used, pusher pet dogs might be made use of to relocate trolleys along a second track positioned below the chain track. This kind of system is referred to as power and also cost-free. Monorail Conveyors Monorail communicating systems have providers to relocate products and are perfect for use over long distances.

The Buzz on Plant Conveyors And Systems

Monorail conveyors use the room above the manufacturing location. In some layouts, the providers lower to the degree of manufacturing and afterwards rise, off the beaten track. Power and also Free Conveyors Power as well as totally free sharing systems are developed to relocate parts with the manufacturing and setting up procedure.

They stop at each station to be worked with as well as after that carry on. Power as well as totally free systems are an unique type of overhanging sharing system. The unique layout of power and also free systems enables an item to be buffered along the communicating course, start and stop immediately, and are very flexible and adjustable.

Inverted Conveyors Inverted conveyors are floor mounted as well as can be utilized as power as well as totally free conveyors. They normally have a drive system that does not entail a belt or chain. Paternoster Conveyors Paternoster conveyors are a vertical communicating system that makes use of equal spaced tons carriers attached to a chain drive, which moves in a continuous loop (Plant Conveyors and Systems).

The 10-Second Trick For Plant Conveyors And Systems

The chain can bending along the straight axis allowing it to make straight turns and is qualified of making upright curves. The numerous kinds of weaves a COE makes enables it to be more functional than typical chain driven conveyors. Skid Conveyor Skid conveyors are an additional kind of floor mounted conveyor that moves products on fixtures that have longitudinal joggers called skids with travel being longitudinally and transversely.

Skid conveyor systems are valued for the efficiency and also silent mode advice of transportation. The variations in skid conveyor systems are due to the lots of parts and control systems that can be consisted of. Friction Conveying System A rubbing sharing system makes use of a motor to drive a friction wheel constructed from non metallic material to create driving force.

Friction sharing systems are a secure option to power as well as cost-free systems with the major benefit of operating cleaner and quieter. They have an adaptable layout, unit building and construction, simple speed altering, can quickly be increased, and also low general expense. The major objective for friction communicating systems is to assist with procedures that have a high manufacturing price.

The smart Trick of Plant Conveyors And Systems That Nobody is Talking About

When the electric motor is turned on, the belt is drawn in between the pulley-blocks. Support group: The assistance system allows the belt to relocate smoothly. click this It is specifically developed to hold the relocating product without drooping. In the layout stage, the weight capability of the frame is established as well as the structure is constructed to satisfy the demands of the procedure.